How Vacuum Bagging Works in Composite Fabrication

-

Table of Contents

“Achieve Perfect Precision: Vacuum Bagging for Flawless Composite Fabrication.”

Vacuum bagging is a widely used technique in composite fabrication that enhances the quality and performance of composite materials. This process involves enclosing a composite layup in a sealed bag and applying vacuum pressure to remove air and excess resin, ensuring optimal fiber wet-out and minimizing voids. By creating a controlled environment, vacuum bagging facilitates uniform pressure distribution during curing, leading to improved mechanical properties and surface finish. The technique is essential in various applications, including aerospace, automotive, and marine industries, where high-strength, lightweight materials are critical. Understanding the principles and mechanics of vacuum bagging is crucial for achieving superior composite structures.

Principles Of Vacuum Bagging In Composite Manufacturing

Vacuum bagging is a widely utilized technique in composite fabrication, primarily due to its ability to enhance the quality and performance of composite materials. At its core, vacuum bagging involves the application of a vacuum to remove air from the composite layup, thereby ensuring a more uniform distribution of resin and a reduction in voids. This process is essential for achieving the desired mechanical properties and surface finish in composite structures, which are increasingly used in industries such as aerospace, automotive, and marine.

The principles of vacuum bagging hinge on the fundamental concepts of pressure differentials and material consolidation. When a vacuum is applied, the atmospheric pressure outside the bag exerts a force on the composite layup, compressing the layers of fabric and resin together. This compression is crucial, as it facilitates the wetting of the fibers by the resin, ensuring that the matrix fully saturates the reinforcement material. Consequently, the elimination of air pockets not only improves the mechanical integrity of the composite but also enhances its overall performance characteristics.

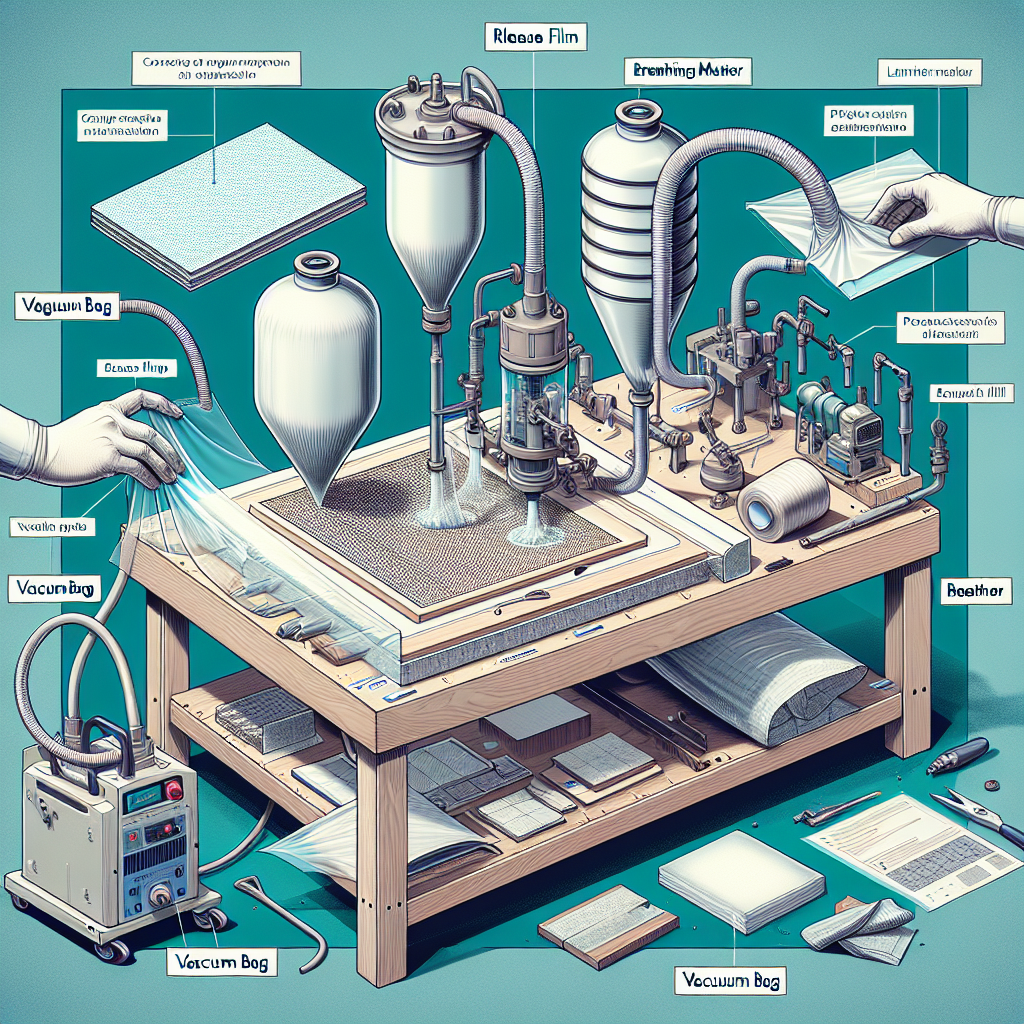

To initiate the vacuum bagging process, the composite layup is first prepared on a mold. This preparation typically involves layering reinforcement materials, such as carbon or fiberglass, with a resin system that may be either thermosetting or thermoplastic. Once the layup is complete, a release film is placed over the surface to prevent the vacuum bag from adhering to the composite. Following this, a breather fabric is added to facilitate the flow of resin and air during the curing process. The vacuum bag is then sealed around the edges, ensuring that no air can escape once the vacuum is applied.

As the vacuum pump removes air from the bag, the pressure differential created between the inside of the bag and the external environment plays a pivotal role in the consolidation of the composite materials. This pressure differential not only compresses the layers but also aids in the removal of volatiles and excess resin, which can lead to defects if not properly managed. The effectiveness of this process is influenced by several factors, including the type of resin used, the thickness of the layup, and the duration of the vacuum application.

Moreover, the curing phase is critical in vacuum bagging, as it determines the final properties of the composite. Depending on the resin system, curing can occur at room temperature or may require elevated temperatures. In some cases, the application of heat during the curing process can further enhance the mechanical properties of the composite by promoting better resin flow and fiber wetting. This is particularly important in high-performance applications where the structural integrity of the composite is paramount.

In addition to improving mechanical properties, vacuum bagging also contributes to a more efficient manufacturing process. By minimizing the presence of voids and ensuring uniform resin distribution, manufacturers can achieve higher quality composites with reduced waste. This efficiency not only lowers production costs but also aligns with the growing emphasis on sustainability in manufacturing practices.

In conclusion, the principles of vacuum bagging in composite manufacturing are rooted in the effective management of pressure differentials and material consolidation. By understanding and applying these principles, manufacturers can produce high-quality composite materials that meet the rigorous demands of various industries. As technology continues to advance, the role of vacuum bagging in composite fabrication is likely to expand, further enhancing the capabilities and applications of composite materials in the modern world.

Benefits Of Using Vacuum Bagging For Composite Parts

Vacuum bagging is a widely adopted technique in the realm of composite fabrication, offering numerous advantages that enhance the quality and performance of composite parts. One of the primary benefits of vacuum bagging is its ability to significantly reduce the presence of voids and air bubbles within the composite material. During the curing process, the vacuum creates a pressure differential that forces the resin to fully saturate the fibers, ensuring a more uniform distribution of the matrix material. This results in a denser, stronger composite that exhibits improved mechanical properties, such as increased tensile strength and stiffness.

In addition to enhancing the structural integrity of composite parts, vacuum bagging also contributes to a more efficient use of materials. By applying vacuum pressure, excess resin is drawn out of the laminate, which not only minimizes waste but also helps in achieving a more optimal fiber-to-resin ratio. This is particularly important in applications where weight savings are critical, such as in aerospace and automotive industries. The reduction in excess resin not only lightens the final product but also improves the overall performance characteristics, making vacuum bagging an essential process for high-performance applications.

Moreover, vacuum bagging facilitates better surface finish on composite parts. The pressure applied during the curing process helps to eliminate surface imperfections, resulting in a smoother and more aesthetically pleasing finish. This is particularly advantageous in industries where appearance is paramount, such as in consumer products and high-end automotive components. The improved surface quality also enhances the adhesion of subsequent coatings or finishes, further elevating the overall quality of the final product.

Another significant benefit of vacuum bagging is its versatility. This technique can be applied to a wide range of composite materials, including carbon fiber, fiberglass, and aramid fiber, making it suitable for various applications across different industries. Whether it is for small-scale projects or large-scale production runs, vacuum bagging can be adapted to meet specific requirements, allowing manufacturers to achieve consistent results regardless of the complexity of the part being produced.

Furthermore, vacuum bagging is a relatively straightforward process that can be implemented with minimal equipment. The basic setup typically involves a vacuum pump, a bagging film, and a sealant tape, making it accessible for both small workshops and large manufacturing facilities. This simplicity not only reduces the initial investment required for equipment but also streamlines the production process, allowing for quicker turnaround times and increased productivity.

In addition to these practical benefits, vacuum bagging also aligns with sustainability goals in composite manufacturing. By minimizing waste and optimizing material usage, this technique contributes to more environmentally friendly production practices. As industries increasingly focus on reducing their carbon footprint, the adoption of vacuum bagging can play a crucial role in promoting sustainable manufacturing processes.

In conclusion, the benefits of using vacuum bagging for composite parts are manifold, encompassing improved mechanical properties, efficient material usage, enhanced surface finish, versatility, ease of implementation, and alignment with sustainability goals. As the demand for high-performance composite materials continues to grow, vacuum bagging stands out as a vital technique that not only meets the rigorous standards of modern manufacturing but also paves the way for innovative applications across various sectors. By leveraging the advantages of vacuum bagging, manufacturers can ensure the production of superior composite components that meet the evolving needs of their industries.

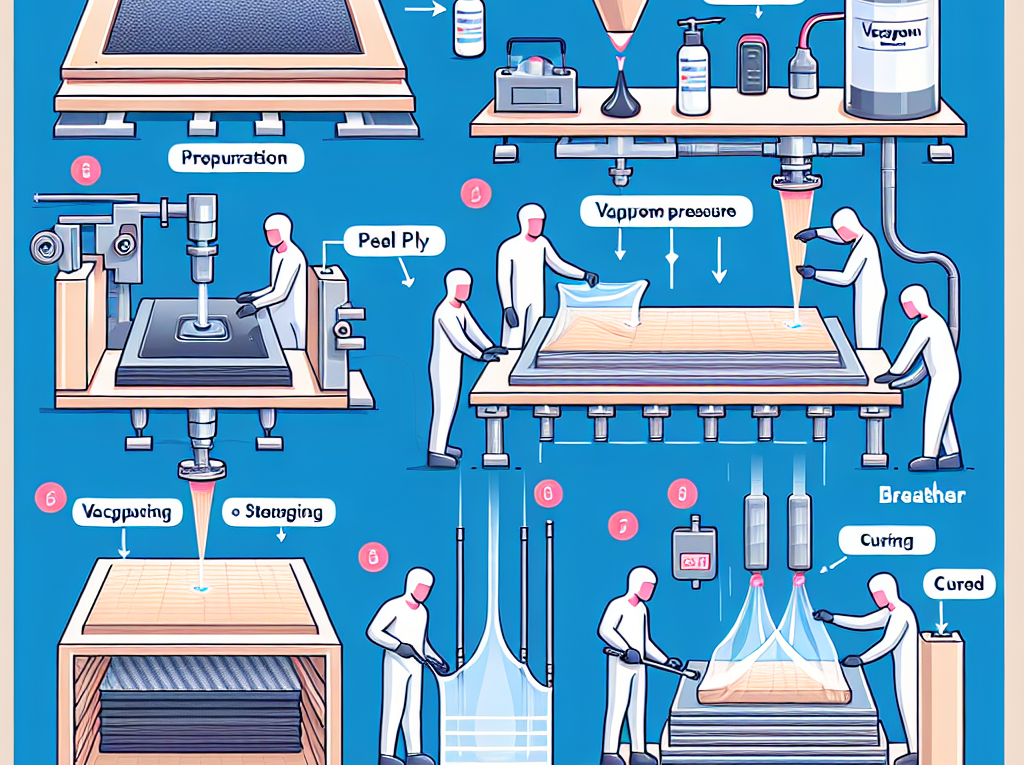

Step-By-Step Process Of Vacuum Bagging In Fabrication

Vacuum bagging is a widely utilized technique in composite fabrication, known for its ability to enhance the quality and performance of composite materials. The process begins with the preparation of the composite layup, which involves arranging layers of reinforcement materials, such as fiberglass or carbon fiber, along with a resin system. This initial step is crucial, as the orientation and alignment of the fibers significantly influence the mechanical properties of the final product. Once the layup is complete, it is essential to ensure that the surfaces are clean and free from contaminants, as any impurities can compromise the bond between the fibers and the resin.

Following the preparation of the layup, the next step involves placing it onto a mold or a release film. The release film serves as a barrier between the composite material and the vacuum bag, preventing the resin from adhering to the bag itself. After positioning the layup, a breather fabric is often added on top. This fabric allows air to escape during the vacuum process while preventing the resin from saturating it. The combination of the layup, release film, and breather fabric creates a composite stack that is ready for vacuum bagging.

Once the stack is assembled, the vacuum bagging process can commence. A vacuum bag, typically made from a flexible, airtight material, is carefully placed over the composite stack. It is crucial to ensure that the bag is large enough to cover the entire layup while allowing for some excess material to create a proper seal. After positioning the bag, the edges are sealed using a vacuum bagging tape, which ensures that no air can escape from the system. This sealing is vital, as it creates a controlled environment that is essential for the vacuum process to be effective.

With the bag securely in place, the next step is to connect a vacuum pump to the system. The pump is activated, and it begins to remove air from the bag, creating a vacuum. As the air is evacuated, the atmospheric pressure outside the bag exerts force on the composite layup, compressing it and ensuring that the resin fully saturates the fibers. This compression is critical, as it helps to eliminate any voids or air pockets that could weaken the final composite structure. The vacuum pressure also aids in the even distribution of resin throughout the layup, promoting uniformity in the material properties.

Once the desired vacuum level is achieved, the resin is typically allowed to cure. This curing process can vary in duration depending on the type of resin used and the specific requirements of the composite material. During this time, the resin hardens, bonding the fibers together and forming a solid composite structure. After the curing period is complete, the vacuum bag is carefully removed, revealing the finished composite part. It is essential to inspect the part for any defects or imperfections, as these can affect its performance in practical applications.

In conclusion, vacuum bagging is a systematic and effective method for fabricating composite materials. By following a step-by-step process that includes preparation, assembly, sealing, vacuum application, and curing, manufacturers can produce high-quality composites with enhanced mechanical properties. This technique not only improves the structural integrity of the materials but also contributes to the overall efficiency of the fabrication process, making it a preferred choice in various industries, including aerospace, automotive, and marine applications.

Q&A

1. **What is vacuum bagging in composite fabrication?**

Vacuum bagging is a process used in composite fabrication where a flexible bag is placed over a composite layup, and air is evacuated from the bag to create a vacuum. This helps to compress the layers of composite material, ensuring better resin distribution and minimizing voids.

2. **What are the benefits of using vacuum bagging?**

The benefits of vacuum bagging include improved fiber-to-resin ratio, enhanced mechanical properties of the final composite part, reduced weight, and a cleaner working environment by minimizing resin spillage and fumes.

3. **What materials are typically used in vacuum bagging?**

Common materials used in vacuum bagging include a vacuum bag film (usually made of polyethylene or nylon), breather fabric to allow air to escape, release films to prevent the composite from sticking to the bag, and sealant tape to ensure an airtight seal.Vacuum bagging is a process used in composite fabrication to enhance the quality and performance of composite materials. It involves placing the composite layup inside a sealed bag and applying vacuum pressure, which removes air and excess resin, ensuring a uniform distribution of materials. This technique helps to eliminate voids, improve fiber-to-resin ratio, and enhance the overall mechanical properties of the final product. By creating a controlled environment, vacuum bagging also aids in achieving better surface finishes and reduces the likelihood of defects, making it a crucial method in the production of high-performance composite components.