Resin Infusion Explained: Step-by-Step

-

Table of Contents

“Master the Art of Resin Infusion: A Step-by-Step Guide to Perfecting Your Craft!”

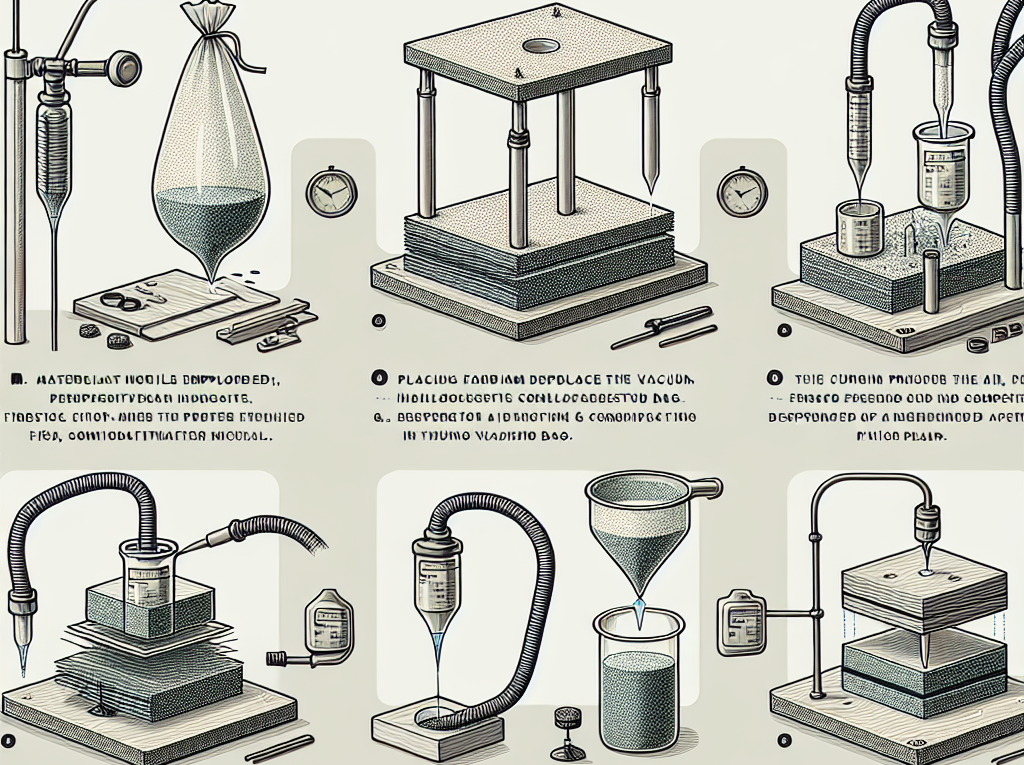

Resin infusion is a composite manufacturing process that involves the use of a vacuum to draw resin into a dry fiber reinforcement material, creating a strong and lightweight composite structure. This method is favored for its ability to produce high-quality parts with minimal waste and improved fiber wet-out. The process typically includes several key steps: preparing the mold and materials, laying out the dry fibers, sealing the mold, applying vacuum, and finally, infusing the resin. Understanding each step is crucial for achieving optimal results in resin infusion, making it a popular choice in industries such as aerospace, automotive, and marine applications.

Overview of Resin Infusion Process

Resin infusion is a sophisticated composite manufacturing process that has gained significant traction in various industries, including aerospace, automotive, and marine applications. This method is particularly valued for its ability to produce lightweight, high-strength components while minimizing waste and enhancing the overall quality of the final product. To understand the resin infusion process, it is essential to explore its fundamental steps, which collectively contribute to the creation of durable composite materials.

The process begins with the preparation of the mold, which serves as the foundation for the composite structure. The mold is typically made from materials such as aluminum or fiberglass, designed to withstand the pressures and temperatures involved in the infusion process. Once the mold is ready, it is coated with a release agent to ensure that the cured composite can be easily removed after the infusion is complete. This initial step is crucial, as it sets the stage for a successful infusion and prevents any damage to the mold or the composite material.

Following the preparation of the mold, the next step involves laying down the reinforcement material, which is often composed of fiberglass, carbon fiber, or aramid fiber. These materials are chosen for their exceptional strength-to-weight ratios and their ability to provide structural integrity to the final product. The reinforcement layers are carefully arranged within the mold, ensuring that they are positioned correctly to achieve the desired mechanical properties. This meticulous arrangement is vital, as it directly influences the performance characteristics of the finished composite.

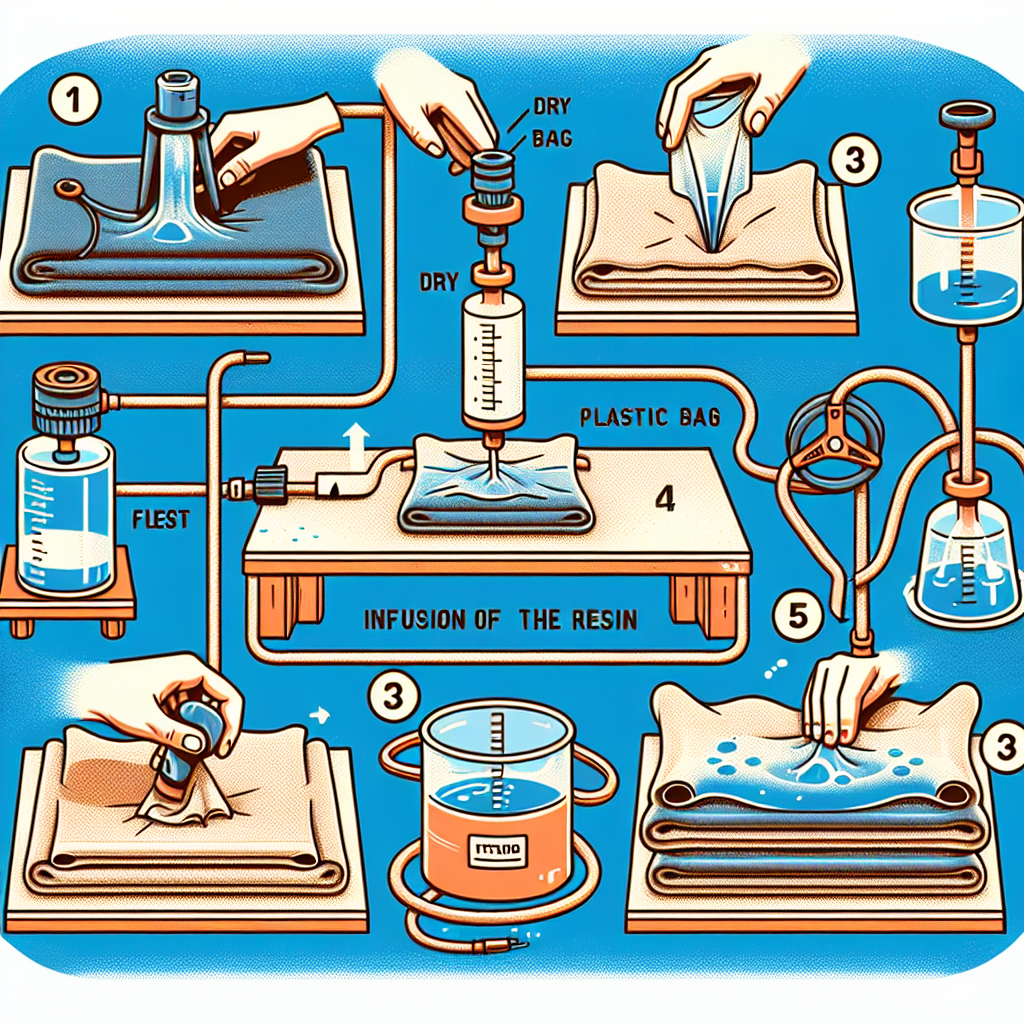

Once the reinforcement material is in place, the infusion process can commence. This is achieved by placing a vacuum bag over the mold and sealing it tightly. The vacuum bag serves a dual purpose: it removes air from the mold, thereby preventing the formation of voids within the composite, and it creates a pressure differential that facilitates the flow of resin. After the vacuum is established, the resin is introduced into the mold through strategically placed injection ports. The resin, often a thermosetting polymer, is drawn into the reinforcement material by capillary action, saturating the fibers and ensuring complete wet-out.

As the resin permeates the reinforcement, it begins to cure, a chemical reaction that transforms the liquid resin into a solid, rigid structure. This curing process can be accelerated by applying heat, depending on the specific resin system used. It is during this phase that the composite material gains its strength and rigidity, making it suitable for various applications. The curing time can vary based on the type of resin and the ambient conditions, but it is essential to allow sufficient time for the resin to fully harden to achieve optimal performance.

After the curing process is complete, the final step involves demolding the composite part. This is done by carefully removing the vacuum bag and extracting the cured component from the mold. The resulting part is often subjected to post-curing treatments or surface finishing processes to enhance its aesthetic appeal and performance characteristics. These additional steps may include sanding, painting, or applying protective coatings, depending on the intended use of the composite.

In conclusion, the resin infusion process is a methodical approach to creating high-performance composite materials. By understanding each step—from mold preparation and reinforcement placement to resin infusion and curing—manufacturers can produce components that meet stringent industry standards while optimizing material usage and minimizing waste. This process not only exemplifies the advancements in composite technology but also highlights the potential for innovation in various fields where lightweight and durable materials are essential.

Essential Materials for Resin Infusion

Resin infusion is a sophisticated process widely utilized in composite manufacturing, particularly in industries such as aerospace, automotive, and marine. To achieve optimal results, it is crucial to understand the essential materials involved in this technique. The primary components include the resin itself, the reinforcement materials, and the infusion equipment, each playing a vital role in the overall success of the infusion process.

To begin with, the resin is the cornerstone of the infusion process. Typically, epoxy resins are favored due to their excellent mechanical properties, chemical resistance, and adhesion capabilities. However, other types of resins, such as polyester and vinyl ester, may also be employed depending on the specific application and desired characteristics of the final product. The choice of resin significantly influences the curing time, viscosity, and overall performance of the composite material. Therefore, it is essential to select a resin that aligns with the project requirements and environmental conditions.

In addition to the resin, the reinforcement materials are equally important in the resin infusion process. These materials provide the structural integrity and strength to the composite. Common reinforcement options include fiberglass, carbon fiber, and aramid fiber. Each type of reinforcement has its unique properties; for instance, carbon fiber is known for its high strength-to-weight ratio, making it ideal for applications where weight reduction is critical. Conversely, fiberglass is often chosen for its cost-effectiveness and versatility. The selection of reinforcement material should be based on the specific performance criteria required for the end product, as well as budget considerations.

Moreover, the infusion process itself necessitates specialized equipment to ensure a successful outcome. A vacuum pump is essential for creating the necessary pressure differential that allows the resin to flow through the reinforcement materials. This equipment must be capable of maintaining a consistent vacuum level throughout the infusion process to prevent air entrapment, which can compromise the integrity of the composite. Additionally, infusion hoses and fittings are required to direct the resin from the reservoir to the mold. These components must be compatible with the chosen resin to avoid any chemical reactions that could hinder the infusion process.

Furthermore, the use of a mold is critical in shaping the final product. Molds can be made from various materials, including aluminum, steel, or composite materials, depending on the complexity of the part being produced and the number of parts required. The mold must be designed to accommodate the flow of resin and allow for proper venting to eliminate air pockets. Proper mold preparation, including surface treatment and release agents, is also necessary to ensure that the finished composite can be easily removed without damage.

In addition to these primary materials, ancillary items such as release agents, peel ply, and breather fabrics may also be utilized to enhance the infusion process. Release agents facilitate the easy removal of the composite from the mold, while peel ply can be used to create a textured surface for subsequent bonding. Breather fabrics help to distribute the resin evenly and assist in the removal of air during the infusion.

In conclusion, understanding the essential materials for resin infusion is fundamental to achieving high-quality composite products. By carefully selecting the appropriate resin, reinforcement materials, and infusion equipment, manufacturers can optimize the infusion process and produce composites that meet stringent performance standards. As the industry continues to evolve, advancements in materials and techniques will further enhance the capabilities of resin infusion, paving the way for innovative applications across various sectors.

Common Challenges and Solutions in Resin Infusion

Resin infusion is a widely used technique in composite manufacturing, offering numerous advantages such as improved mechanical properties and reduced void content. However, like any complex process, it presents its own set of challenges that can affect the quality and efficiency of the final product. Understanding these challenges and their corresponding solutions is crucial for anyone involved in resin infusion.

One of the most common challenges encountered during resin infusion is the issue of air entrapment. Air bubbles can become trapped within the composite material, leading to defects that compromise the structural integrity of the finished product. To mitigate this problem, it is essential to ensure that the vacuum bagging process is executed correctly. This involves using high-quality vacuum bags and ensuring that all seams are properly sealed. Additionally, employing a vacuum pump with sufficient capacity can help maintain a consistent vacuum level, thereby reducing the likelihood of air entrapment.

Another significant challenge is achieving uniform resin distribution throughout the fiber reinforcement. Inconsistent resin flow can lead to areas of dry fiber, which can weaken the composite. To address this issue, it is advisable to use flow media, such as porous fabrics or specialized flow channels, which facilitate even resin distribution. Furthermore, careful consideration of the resin viscosity is crucial; using a resin with an appropriate viscosity for the specific application can enhance flow characteristics and ensure that the resin saturates the fibers uniformly.

Temperature control during the infusion process is also a critical factor that can influence the outcome. If the temperature is too low, the resin may not flow adequately, while excessively high temperatures can lead to premature curing. To overcome this challenge, it is important to monitor the ambient temperature and, if necessary, use heating blankets or other temperature control methods to maintain an optimal environment for the resin infusion. This careful regulation of temperature not only aids in achieving proper resin flow but also ensures that the curing process occurs as intended.

Moreover, the choice of materials plays a significant role in the success of resin infusion. Incompatibility between the resin and the reinforcement materials can lead to poor adhesion and compromised mechanical properties. To prevent this issue, it is essential to select compatible materials that are specifically designed for use with the chosen resin system. Conducting preliminary tests to evaluate the compatibility of materials can save time and resources in the long run.

In addition to these technical challenges, there are also logistical considerations that can impact the resin infusion process. For instance, the scale of production can affect the efficiency of the infusion. In large-scale operations, it may be beneficial to implement automated systems that can streamline the infusion process and reduce labor costs. Conversely, for smaller projects, manual techniques may be more appropriate. Understanding the scale of production and adapting the approach accordingly can lead to improved outcomes.

Finally, proper training and experience are vital in overcoming the challenges associated with resin infusion. Ensuring that all personnel involved in the process are well-trained and knowledgeable about best practices can significantly enhance the quality of the final product. Continuous education and hands-on experience can help teams identify potential issues early and implement effective solutions.

In conclusion, while resin infusion presents several challenges, a proactive approach that includes careful planning, material selection, and personnel training can lead to successful outcomes. By addressing these common challenges with effective solutions, manufacturers can harness the full potential of resin infusion technology, resulting in high-quality composite materials that meet the demands of various applications.

Q&A

1. **What is resin infusion?**

Resin infusion is a composite manufacturing process where a dry fiber reinforcement is placed in a mold, and resin is drawn into the fibers under vacuum pressure, allowing for a thorough saturation and creating a strong, lightweight composite part.

2. **What are the key steps in the resin infusion process?**

The key steps include preparing the mold and dry fibers, sealing the mold, placing the dry fibers inside, connecting the vacuum and resin lines, applying vacuum to remove air, and then introducing the resin to saturate the fibers.

3. **What are the advantages of using resin infusion?**

Advantages include improved fiber wet-out, reduced void content, better control over resin distribution, and the ability to create complex shapes with a high strength-to-weight ratio.Resin infusion is a composite manufacturing process that involves the use of a vacuum to draw resin into a dry fiber reinforcement, resulting in a strong and lightweight material. The step-by-step process includes preparing the mold, laying down the dry fibers, sealing the mold, connecting the resin supply, applying vacuum pressure, and allowing the resin to cure. This method is favored for its efficiency, reduced waste, and ability to produce complex shapes with high-quality finishes. In conclusion, resin infusion is a valuable technique in composite manufacturing, offering significant advantages in terms of material properties and production efficiency.